SulFeLox® – Low Hazard Iron Salt

SulFeLox®

Introducing SulFeLox®: a buffered iron solution that combines the effectiveness of iron salts with the safety benefits of calcium nitrate – all at less cost.

SulFeLox® is specifically designed to control H2S in wastewater collection systems by binding it into non-volatile ferrous sulfide (FeS). It contains no free acid and has a lower hazard rating than traditional iron salt technologies, and equal or lower than calcium nitrate, enabling use in residential and commercial areas.

SulFeLox® has the benefits of traditional iron solutions (i.e., efficient durational control, natural regeneration and long-term effects in downstream gravity sewers and treatment plant processes) without the downsides (wastewater pH depression or consumption of alkalinity). It can also be dosed at higher concentrations than traditional iron salts without negatively impacting pH and alkalinity.

SulFeLox® can go anywhere nitrates can and is specifically designed to replace nitrate where it performs the worst – in long, slow-moving, sulfide generating sewers. Typical applications for SulFeLox® can substitute for nitrate on a 1:2 to 1:3 basis, meaning significantly fewer deliveries, and approximately 15-20% less cost. Furthermore, for biological nutrient removal (BNR) plants, SulFeLox® does not result in the uptake of soluble carbon into heterotrophic biomass as does the use of nitrate, and thus can reduce downstream sulfide production, and the need for supplemental carbon at the treatment plant.

Additionally, transitioning from calcium nitrate to SulFeLox in the collection system can synergistically use the collection system to generate volatile fatty acids (VFAs), which are critical to the performance of the latest generation of BNR processes.

Read here how SulFeLox® effectively replaced calcium nitrate in Bakersfield, CA. USP_Bakersfield_CaseStudy

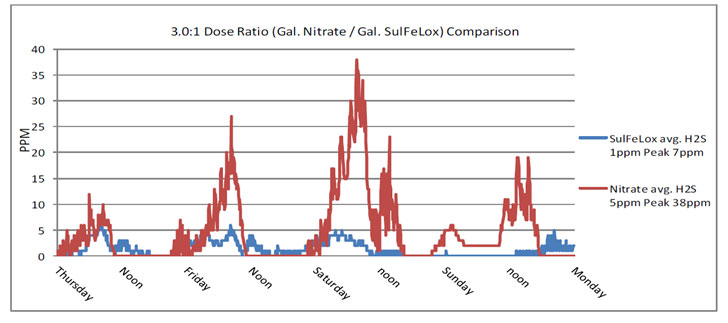

SulFeLox® Performance Comparison to Calcium Nitrate

Several field tests have shown that SulFeLox® controls dissolved sulfide and vapor H2S to levels similar to calcium nitrate, but at less than half the volumetric feed rate, resulting in significant cost savings.

SulFeLox® can be regenerated and re-used multiple times for downstream odor control in the collection system, primary clarifiers and biosolids, as well as, for CEPT, P-removal, struvite / biogas-H2S control, or dewatering improvements when combined with USP’s PRI-TECH®.

SulFeLox® Benefits:

- More efficient and cost-effective dosing, even with increased retention times in the sewer line

- Iron regeneration: Turbulence in the line oxygenates the water, freeing up iron to control even more sulfide downstream without additional cost

- Drives down dosage rates: Iron reduces sulfide formation in the biofilm, minimizing the amount of sulfide needed to be treated

- Fewer deliveries to residential areas, as typically 2–4 times less product is needed for effective treatment

- Quicker sulfide treatment than bio-mediation, which requires several hours for treatment

- Decreased production of floating solids compared to nitrate, lowering the risk of air relief valve (ARV) blockage issues in force mains and the appearance of floating solids in wet wells, slow-moving gravity sewers, and clarifiers

- Approximate immediate savings of 15–20%, with the potential for further savings as SulFeLox® suppresses sulfide production in the biofilm, decreasing dosage requirements

- Non-corrosive to skin

USP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696