Hydrogen Peroxide

Hydrogen Peroxide - Wastewater

USP Technologies is the leading supplier of hydrogen peroxide for water and wastewater treatment and has over 25 years of experience. We are able to supply all grades of hydrogen peroxide in bulk or totes, including 27% refinery grade and food grade peroxides. Learn more about solution properties here.

Why use hydrogen peroxide in your water/wastewater system?

USP Technologies has over 25 years of experience as providers of hydrogen peroxide. We look forward to assisting you in your application needs.

Related Case Studies

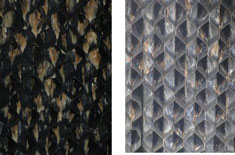

The unique properties of hydrogen peroxide (H2O2) make it a good technology for keeping cooling loops, process water loops and heat exchangers clean from fouling that can occur due to various contaminants in the water.

Learn More

A Midwest wastewater treatment plant was struggling with problematic hydrogen sulfide (H2S) levels at two points within their facility arising from biosolids processing.

Learn More

A field demonstration was initiated in February 2014 by the Suffolk County Department of Public Works (SCDPW) to quantify the impacts of Peroxide Regenerated Iron-Technology (PRI-TECH®).

Learn MoreUSP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields